GENEL BİLGİLER

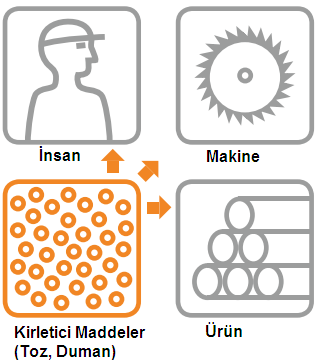

Dust is unavoidably released in production process that use powdered materials and processes such as grinding or filling. This is also true for sawing, grinding or abrading stone, wood or metals. Fumes and gasses usually accompany these dusts.

The ASD Series Suction and Filtration Systems protect employees and the working environment with their specially designed gas and vapor decontamination and elimination equipment, as well as reducing operating costs by protecting your equipment from harmful emissions.

Three Different Harmful Effects of Gases and Vapors

The dusts that are released by processes such as grinding, abrading or filling can have toxic and even carcinogen effects on lungs.

The smaller the dust particles, the higher are their impact. Smaller particles can reach the alveoli in the lungs and lead to irremediable damage. Additionally, grimy films that are created on the machinery and the products can cause serious damages.

TEKNİK BİLGİLER

Applications:

Grinding, carving, abrasion, cleaning, transfilling, polishing etc.

Specifications:

- Mobile unit with wheels,

- Quiet modular design,

- Easy to use and easy to replace filter design,

- Electrostatic paint coated stainless steel body,

- Front panel control elements,

- On and off button.

Volume Control: Allows gradual adjustment of the suction capacity.

Filter Capacity Gauge: Provides optical monitoring for particle filters.

Technical Specifications:

| Device version | ASD 200 MD.14 | ASD 200 HD.10 | ASD 200 HD.12 | ||

| Max. air flow | m³/h | 635 | 210 | 220 | |

| Max. suction power | Pa | 3,200 | 20,700 | 22,000 | |

| Min. capacity | m³/h/Pa | 250/2,200 | 120/13,000 | 120/12,000 | |

| Dimensions (WxDxH) | mm. | 390 x 400 x 600-1,300* (*Height according to filter use) |

|||

For more information on suction filter equipment and custom solutions for your needs, contact us.

DÖKÜMANLAR

Toz ve Duman Arındırma Üniteleri- ASD SERİSİ