GENEL BİLGİLER

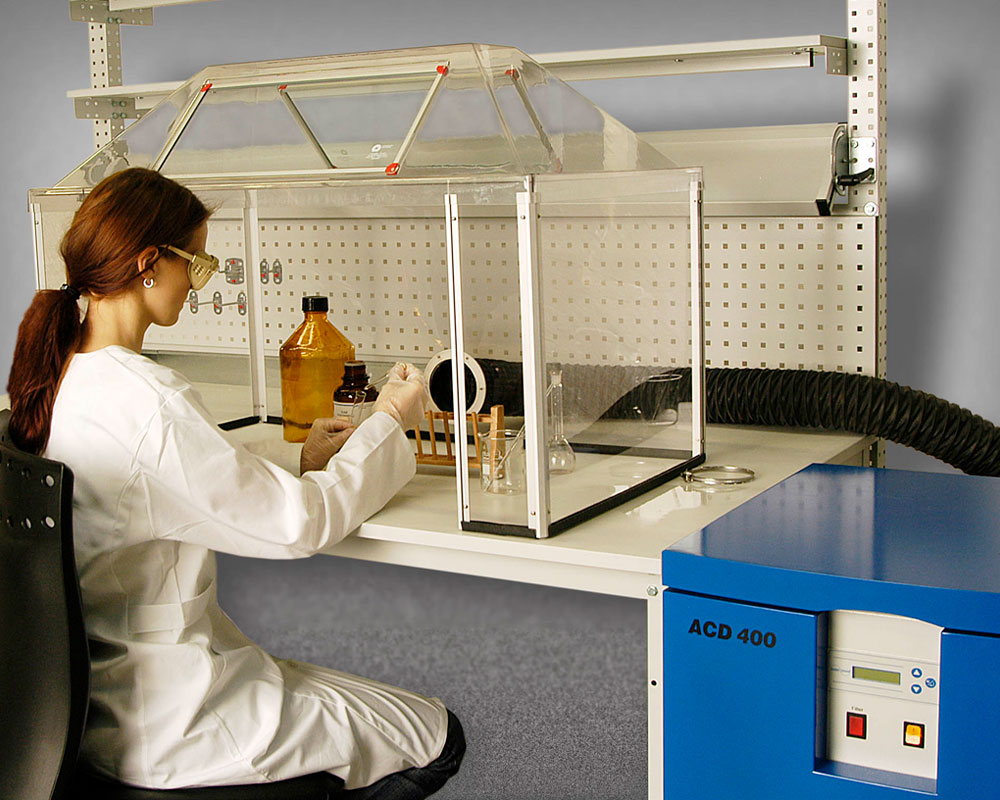

Polluting gasses, vapors and odors are released in to the workplace atmosphere during many industrial processes such as chemistry, pharmaceutical, food, machine, metallurgy and automotive industries. The ACD Series Suction and Filtration Systems protect employees and the working environment with their specially designed gas and vapor decontamination and elimination equipment, as well as reducing operating costs by protecting your equipment from harmful emissions.

Three Different Harmful Effects of Gases and Vapors

Hazardous gases and acid and solvent vapors released during chemical processes cause irritation in eyes and lungs. Certain vapors and gases can cause serious intoxication even at very low concentrations and they might trigger explosive conditions when combined with other hazardous elements in the workplace.

Gases and vapors in the atmosphere are usually accompanied by particles and aerosols. This combination can create a grimy film on your machinery and products and cause serious damages.

TEKNİK BİLGİLER

Applications:

Adhesion, lamination, varnishing, pre-treatment, printing, moulding etc.

Specifications:

- Mobile unit with wheels,

- Quiet modular design,

- Electrostatic paint coated stainless steel body,

- Front panel control elements,

- On and off button.

Volume Control: Allows gradual adjustment of the suction capacity.

Filter Capacity Gauge: Provides optical monitoring for particle filters.

Technical Specifications:

| Product type | ACD 200 MD.11 A6 | ACD 200 MD.14 A6 | ACD 200 HD.10 A6 | ACD 200 HD.12 A6 | |

| Max. air flow | m³/h | 190 | 635 | 210 | 220 |

| Max. suction power | Pa | 3,200 | 3,200 | 20,700 | 22,000 |

| Min. capacity | m³/h/Pa | 80/1,900 | 250/2,200 | 120/13,000 | 120/12,000 |

| Dimensions (width x depth x height) | mm | 390 x 400 x 610-1,270* (Filter selection according to filter use) |

|||

For more information on suction filter equipment and custom solutions for your needs, contact us.

DÖKÜMANLAR

Gaz, Buhar ve Koku Arındırma Üniteleri- ACD SERİSİ