GENEL BİLGİLER

Soldering is the process of attaching metal pieces together or drawing links for transferring currents, using certain alloys as filler. Automatic soldering systems or manual soldering releases fumes into the working environment.

The LRA Series Suction and Filtration Systems protect employees and the working environment with specially designed soldering fume decontamination and elimination equipment, as well as reducing operating costs by protecting your equipment from harmful emissions.

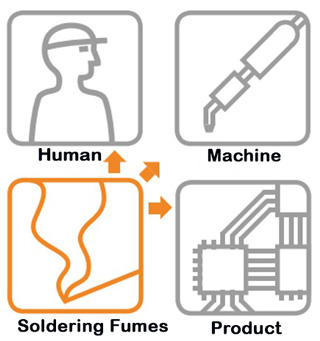

Three Different Harmful Effects of Soldering Fumes

What is perceived as soldering fumes consists mainly of the degradation products from fluids added to sticky aerosols, soldering alloys and cleaning product residues.

These pollutants that are released in the working environment can have severe negative effects on human health as well as causing air pollution. Additionally, these can create a grimy film outside and inside your machinery and products and cause serious damages.

TEKNİK BİLGİLER

Applications:

Manual soldering, robotic soldering, automatic soldering systems.

Specifications:

- Mobile unit with wheels,

- Quiet modular design,

- Easy to use and easy to replace filter design,

- Electrostatic paint coated stainless steel body,

- Front panel control elements,

- On and off button.

Volume Control: Allows gradual adjustment of the suction capacity.

Filter Capacity Gauge: Provides optical monitoring for particle filters.

Technical Specifications:

| Device version | LRA 200 MD.11 | LRA 200 MD.14 | LRA 200 HD.10 | LRA 200 HD.12 | ||

| Max. air flow | m³/h | 190 | 635 | 210 | 220 | |

| Max. suction power | Pa | 3,200 | 3,200 | 20,700 | 22,000 | |

| Min. capacity | m³/h/Pa | 80/1,900 | 250/2,200 | 120/13,000 | 120/12,000 | |

| Dimensions (WxDxH) | mm | 390 x 400 x 610-1,270* (Height according to filter use) |

||||

For more information on suction filter equipment and custom solutions for your needs, contact us.

DÖKÜMANLAR

Lehim Dumanı Arındırma Üniteleri- LRA SERİSİ